√99以上 yield strength calculation excel 225492-Yield strength calculation excel

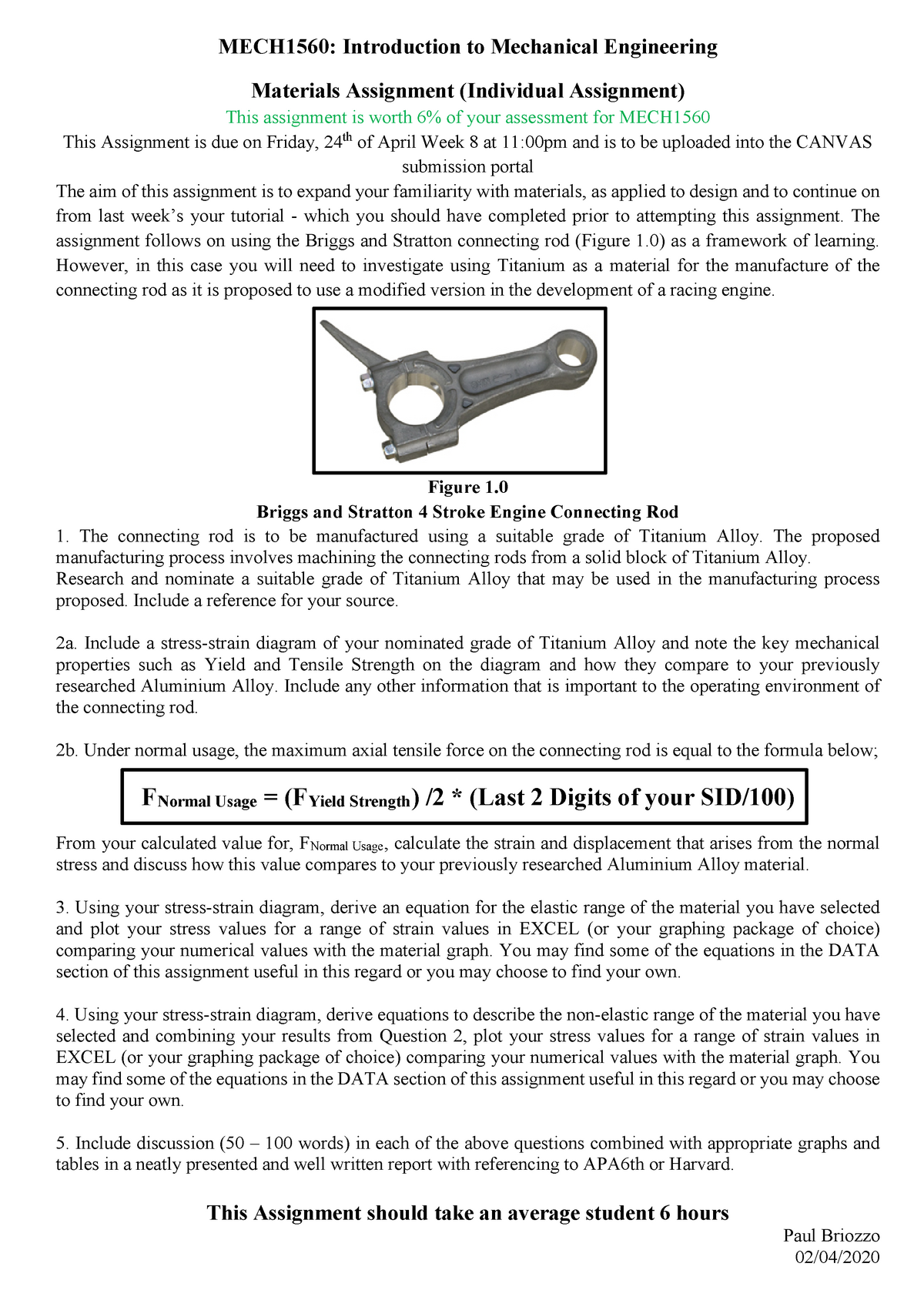

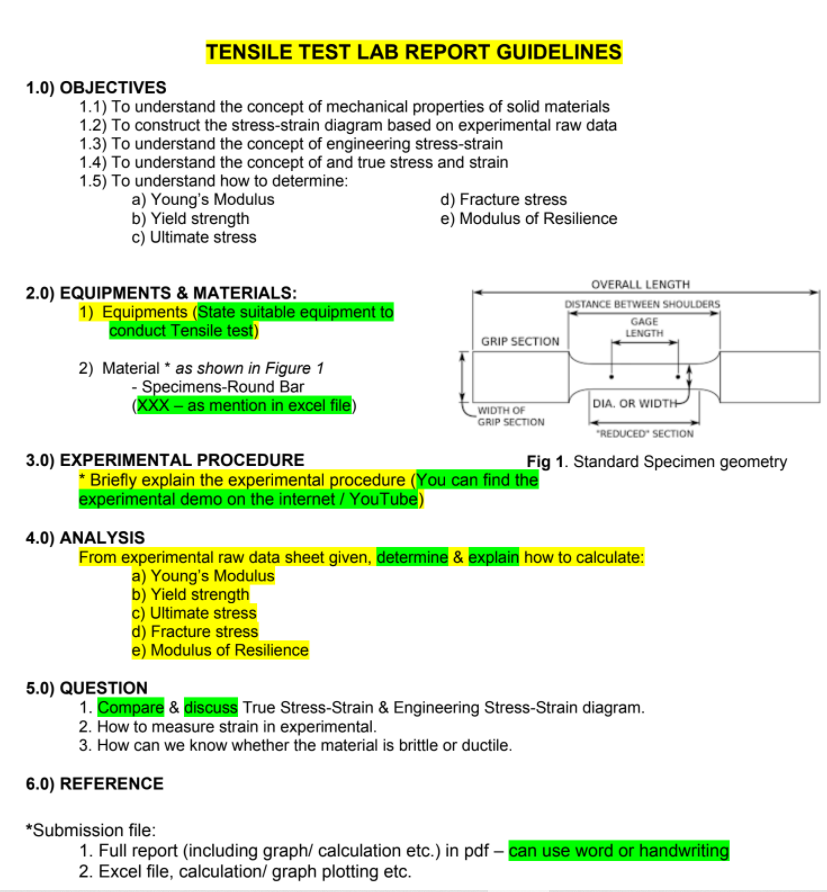

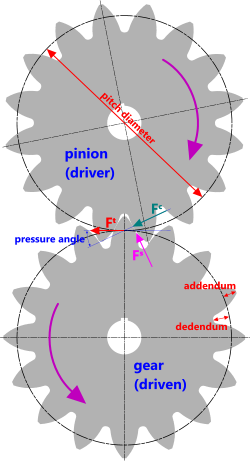

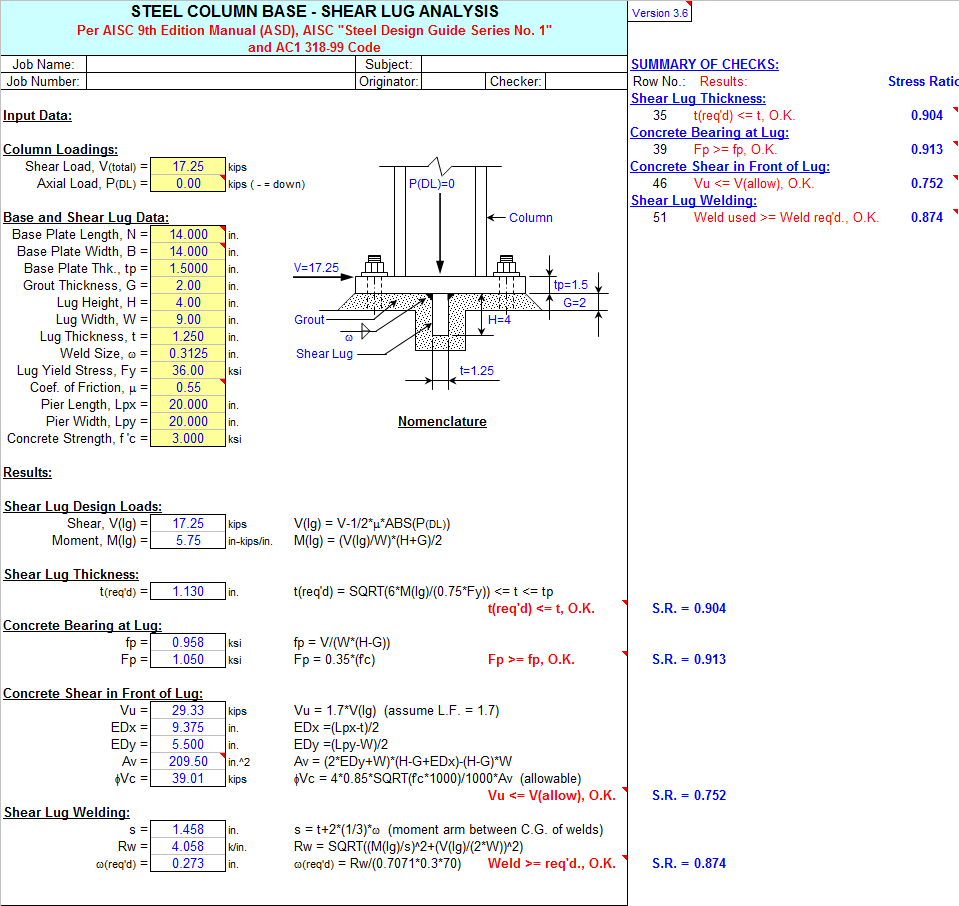

Fy = yield strength of base metal (ksi) E70XX weld electrode is assumed above (70 ksi yield) Case 1 For fillet weld on one side of material thickness t(min) = 1031*w (for Fy = 36 ksi material) t(min) = 0742*w (for Fy = 50 ksi material) Case 2 For fillet weld on both sides of material thickness t(min) = 62*w (for Fy = 36 ksi material)If the material yield strength equals 30,000 pounds per square feet and the wall thickness is 3 inches 30,000 x 3 = 90,000 Multiply your answer by 2 Using the example in Step 1 90,000 x 2 = 180,000 Multiply the pipe's outside diameter by the pipe's safety factorT = K F d (1 l/100) (1) where T = wrench torque (Nm, lbf ft) K = constant that depends on the bolt material and size d = nominal bolt diameter (m, ft) F = axial bolt force (N, lbf) l = lubrication factor (%) Typical values for K with mildsteel bolts in range 1/4" to 1" normal dry K = 02

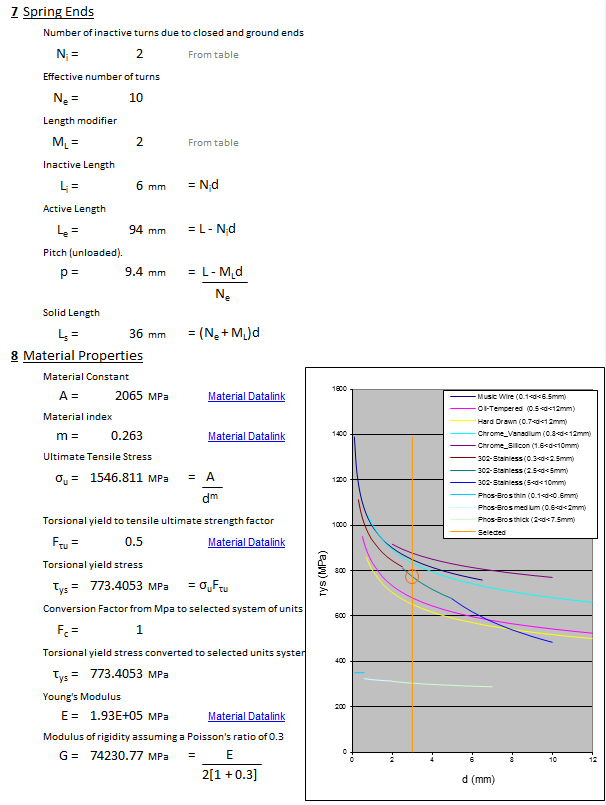

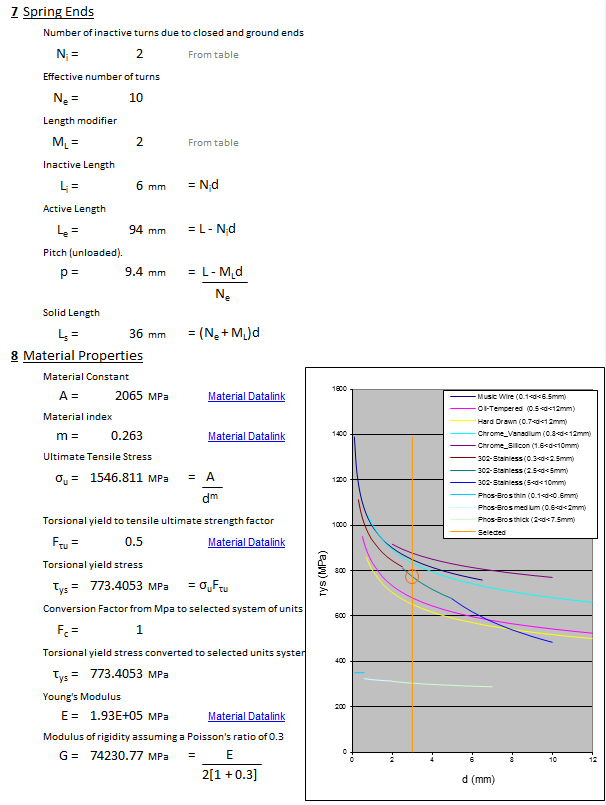

Helical Spring Design Guide Xls

Yield strength calculation excel

Yield strength calculation excel-Pa = 2AE (where A is the strain factor and E is the Young's modulus {yield stress = AE})Basis is not 04

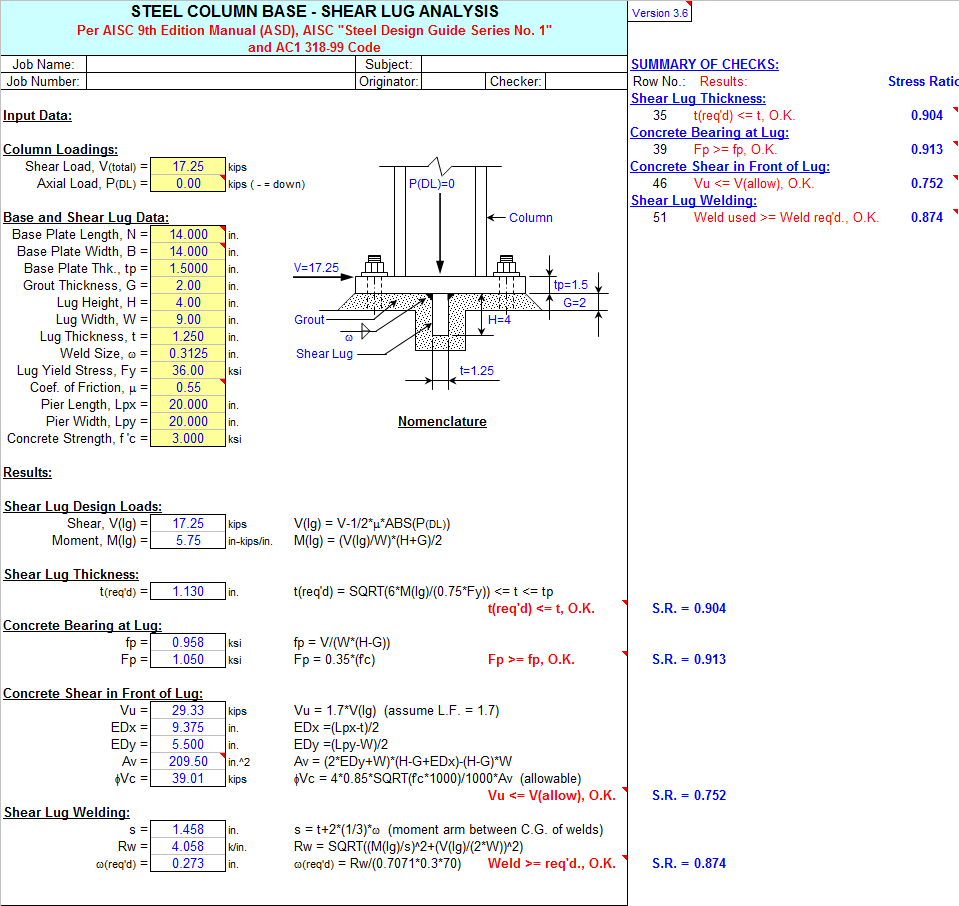

Baseplt9 Xls

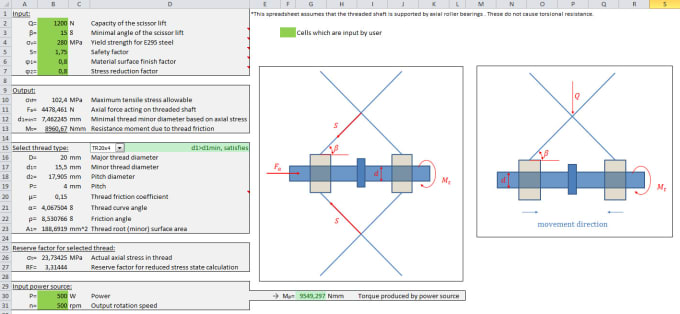

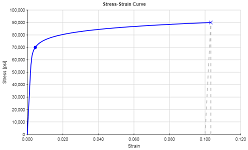

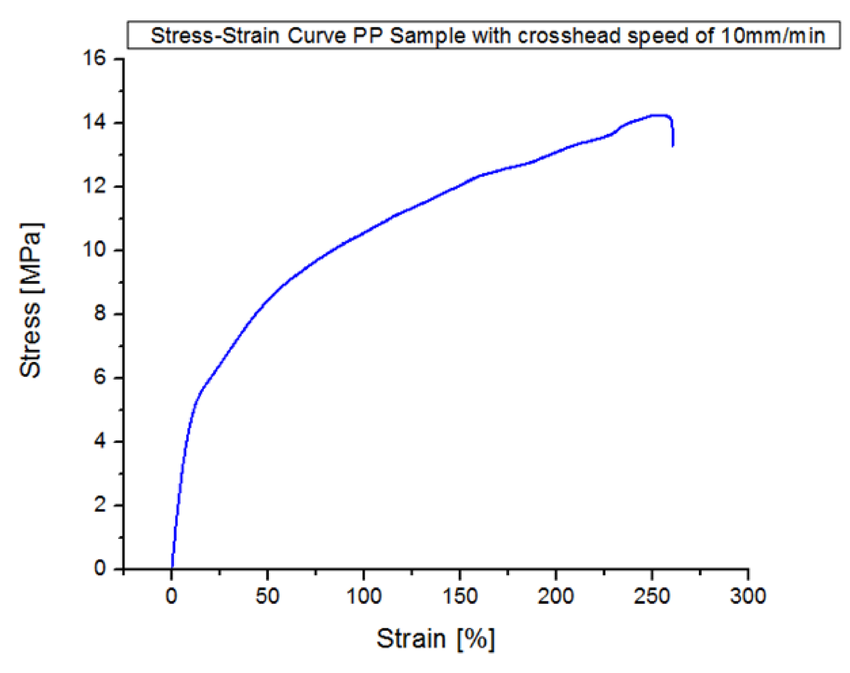

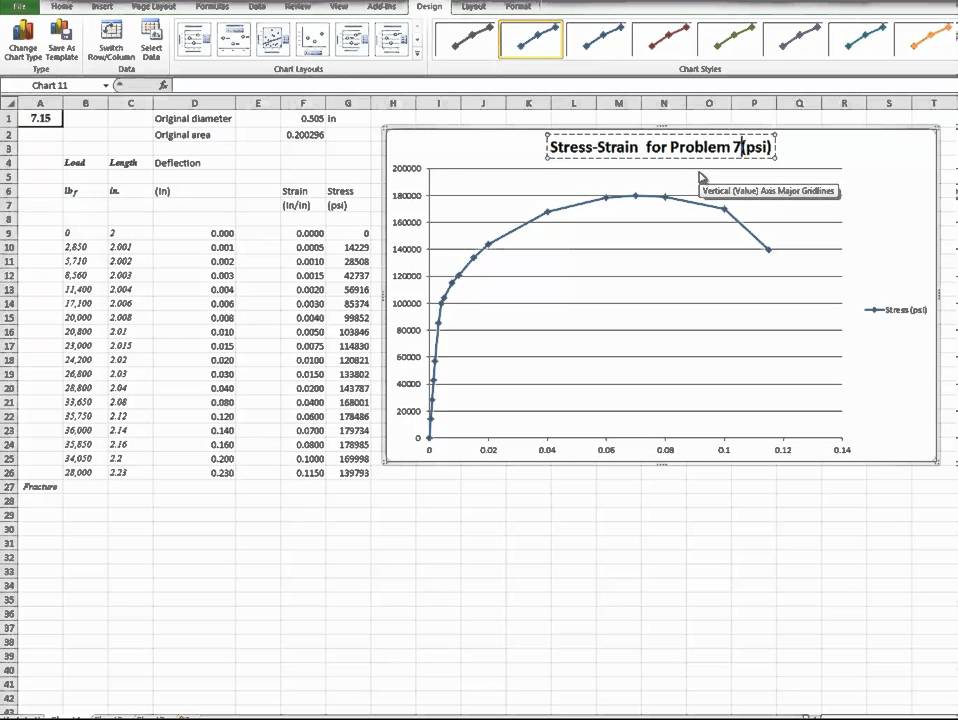

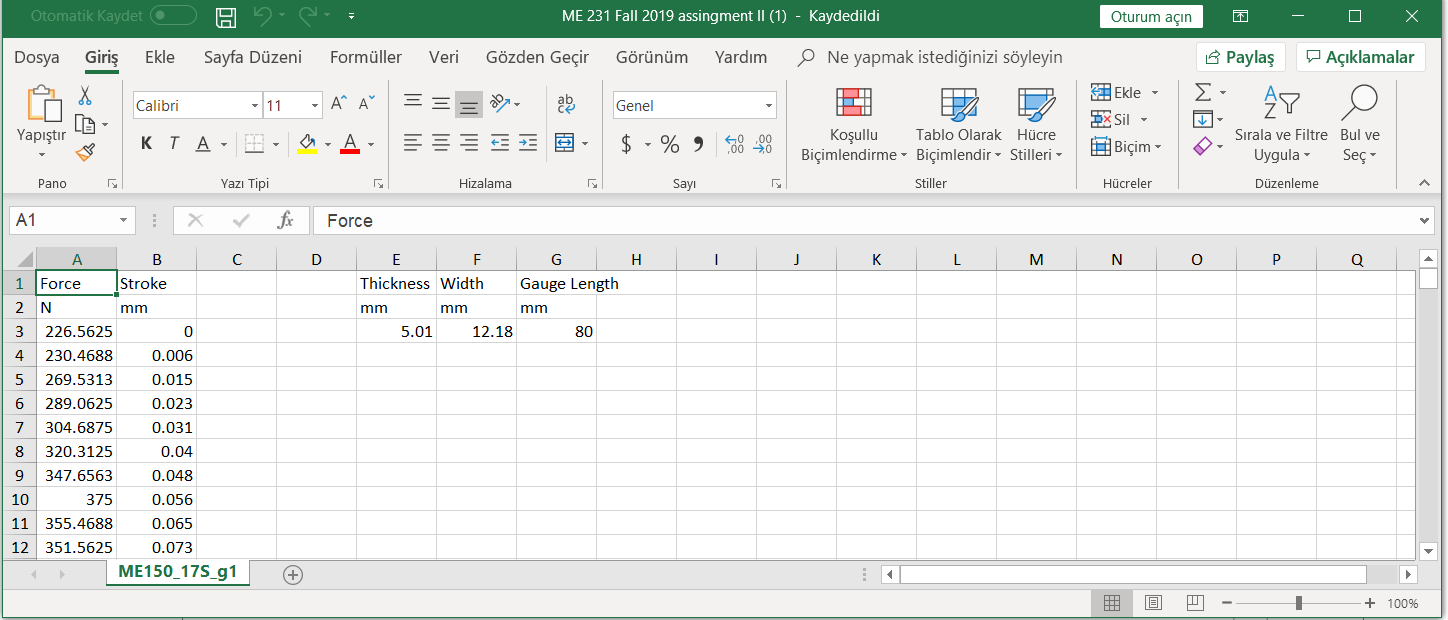

CALCULATIONS AND ANALYSIS See Stress Calculation Spreadsheet for sources of equations, sources of constants and material properties, and additional calculations Impact Analysis When comparing this to the shaft's yield strength, a factor of safety of 133 is calculatedIn this Microsoft Excel to create Stress/Strain Curves from a sample set of data and then determine the Young's Modulus from sample DataThis excercise is oPr or redemption are = 0 settlement >= maturity;

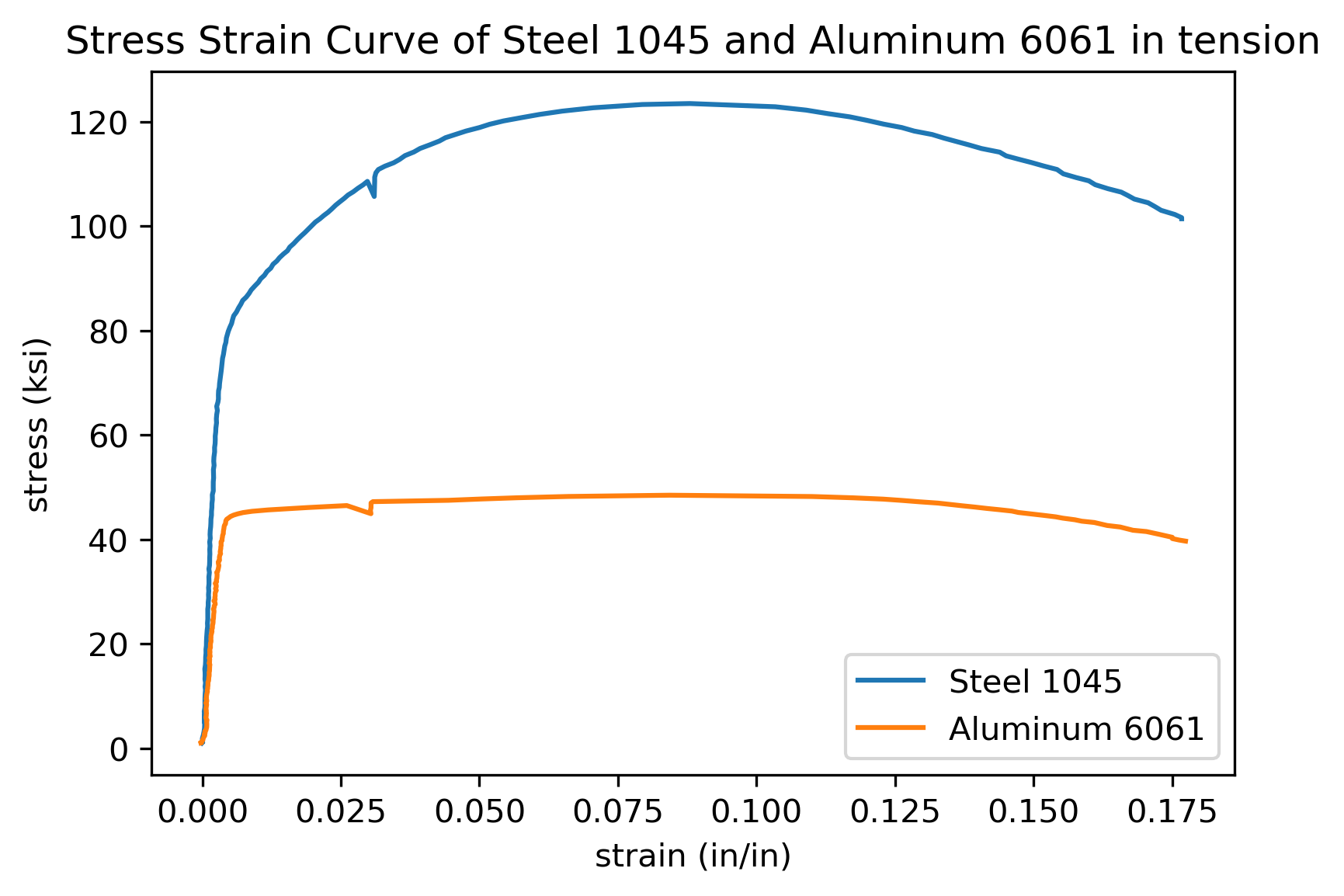

Online metal weight calculator which helps to calculate the weight of Steel Plate metal Steel Plate Weight Calculation Material Alloy Steel Aluminum Beryllium Brass Bronze Cast Iron Columbium Copper Copper Alloys Gold Lead Magnesium Molybdenum Nickel Plastic Silver Stainless Steel Tantalum Titanium Tungsten Zinc ZirconiumIn Excel, dates are serial numbers Settlement, maturity, frequency, and basis are truncated to integers;Tensile Yield Strength, Fty = 35 ksi Factor of Safety on Yield Strength, ny = 165 Allowable Tensile Stress, F = 21 ksi Tensile Ultimate Strength, Ftu = 38 ksi Factor of Safety on Ultimate Strength, nu = 195 Coefficient for Tension Members, kt = 100 Allowable Tensile Stress, F = 195 ksi Controls Vertical Tensile Stress Applied, TVert = 199 ksi OK

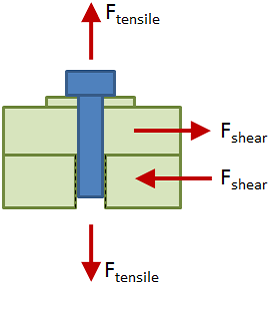

Additionally, the shear strength of the base metal must also be considered φ Rn = 09 x 06 Fy x area of base metal subjected to shear where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x LwIf any of the following are true rate ;Length Length of engagement The distance that the two THREADED regions engage The typical minimum recommended value is 15 times the major bolt diameter

Load Extension Diagram Leaving Certificate Engineering Notes

What Is 0 2 Of Offset Method In Yield Strength Quora

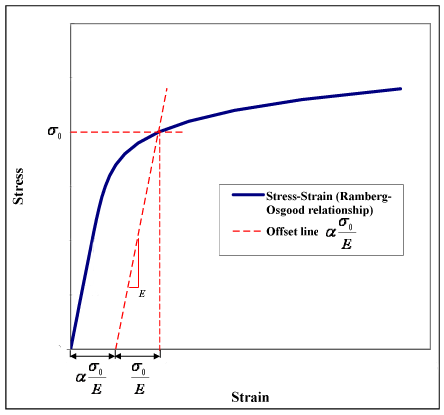

Now select the Y=f (X) command on the Generate menu The equation we want is simply (in this case) "* (x00)" (00 microinches/inch = 02% strain) For the from X value use 00 (or any smaller value);For calculation of the true stressstrain material curve, the equations are and References by three parametres NACA TN 902 yield stregth values NACA TN927 1 Ramberg, W and Osgood W R Description of stressstrain curves 2 FAA FAR MMPDS01 The stressstrain curves calculated here are useful for non linear calculationsNote that the equation for maximum compressive stress is a function of the average stress, P/A, and so the value P crit/A is the value of the average stress at which the maximum compressive stress in the column equals the material yield strength σ crit = P crit / A

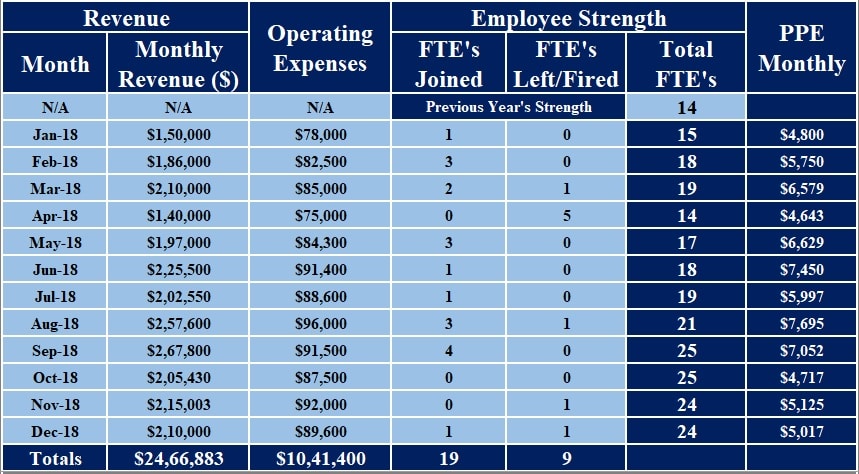

Download Profit Per Employee Calculator Excel Template Exceldatapro

Engarc L Offset Yield Method

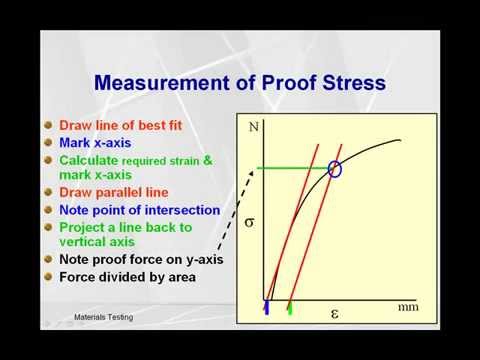

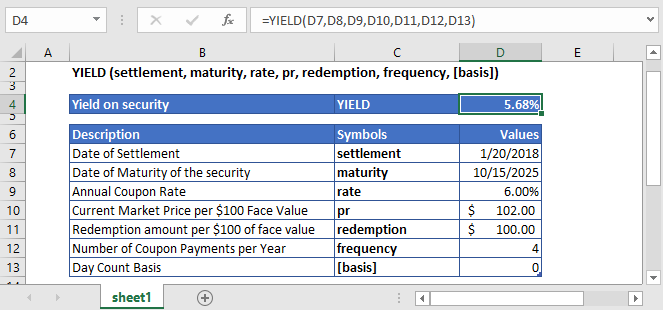

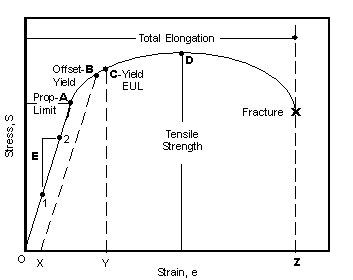

Select the cell "G15" where the YIELD function needs to be applied Click the insert function button (fx) under the formula toolbar, a dialog box will appear, type the keyword "YIELD" in the search for a function box, YIELD function will appear in select a function box Double click on the YIELD functionThe properties of the beam and section are specified by typing directly into the input fields Length of Beam is the total including all spans of the beam, in mm or ft Young's Modulus is set to a default value of 0,000 MPa or ksi for structural steel, but can be edited by the user Area of the CrossSection is specific to the beam section selected, and is defaulted to the valuesStart drawing a line parallel to the stressstrain curve until it meets the curve at some point on the curve Draw a horizontal line from the meeting point until it meets the vertical (stress) axis Measure the value that will be the yield point stress corresponding to 02% of strain Fig source Yield (engineering) Wikipedia

How Can I Determine The 0 2 Yield Stress From My Stress Strain Graphs

Http Uni Obuda Hu Users Grollerg Materials science lab Mechanical properties 15 Pdf

NOMINAL THICKNESS AREA YIELD;Box and pin tensile rating To use the search algorithm, the user must enter the OD, ID, Pitch, and Yield Strength The program then takes over and performs the search based on the constraints input by the user After performing the algorithm, the program then displays the results in order of increasing maximum allowable tensile strength differenceAlternatively, for wire rope with multiple filament diameters, you need to find an equivalent diameter with the following proviso;

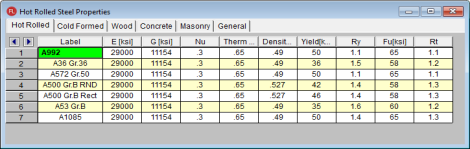

Material Properties

Reinforced Concrete Design Engineer S Outlook

How to Calculate Bond Yield to Maturity Using Excel Open a Blank Excel Spreadsheet In Excel click "File" then "New" using the toolbar at the top of the screen Set Up the Assumption Labels Enter the Dates Enter the settlement date into cell B2 The settlement date is when an investor buys theYield Strength This is tricky for wood as there generally is not a yield specification available What we will use is the data for the "Modulus of Rupture " specification which for pine, eastern is = approximately 4,900 psi Modulus of Rupture is the theoretical value where the wood breaks or fails not good for our car or engine if thisOnline metal weight calculator which helps to calculate the weight of Steel Plate metal Steel Plate Weight Calculation Material Alloy Steel Aluminum Beryllium Brass Bronze Cast Iron Columbium Copper Copper Alloys Gold Lead Magnesium Molybdenum Nickel Plastic Silver Stainless Steel Tantalum Titanium Tungsten Zinc Zirconium

Tensile Test Report

Using Stress Strain Data In Solidworks Simulation Design Engineering

With that additional information, using the Yield() function to calculate the yield to maturity on any date is simple Insert the following function into B18 =YIELD(B6,,B4,B13,,B10,B11) and you will find that the YTM is 950% Notice that we didn't need to make any adjustments to account for the semiannual paymentsNOMINAL THICKNESS AREA YIELD;A = number of days from the beginning of the coupon period to the settlement date (accrued days) DSR = number of days from the settlement date to the redemption date E = number of days in the coupon period If there is more than one coupon period until redemption, YIELD is calculated through a hundred iterations

Minimum Pipe Wall Thickness Calculator Excel Spreadsheet

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Modulus of Elasticity for Wood = 99 x 10 6 ( 990,000) psi (pounds per square inch) Yield Strength This is tricky for wood as there generally is not a yield specification available What we will use is the data for the "Modulus of Rupture " specification which for pine, eastern is = approximately 4,900 psiYield Strength, Modulus of Elasticity, Ultimate Strength of Selected Materials A straight line is drawn through Point (D) at the same slope as the initial portion of the stressstrain curve The point of intersection of the new line and the stressstrain curve is projected to the stress axisThe YIELD Function is categorized under Excel Financial functions It will calculate the yield on a security that pays periodic interest The function is generally used to calculate bond yield As a financial analyst, we often calculate the yield on a bond to determine the income that would be generated in a

Mech1560 Introduction To Mechanical Engineering Materials Assignment Studocu

Isbt212 04 3 Stress And Strain Proportional Limit And Yield Strength Youtube

GRAIN YIELD CALCULATION (Total Grain Harvested / Grain Factor) X (100 % Average Moisture) = Total bu/field (100 % Standard Storage Moisture) Total bu/field = Grain Yield (bu/acre) Total Acres Harvested Total bu/field Grain Yield (bu/acre) IMPORTANT Attach all weight tickets and/or receipts to this sheetDesign Shear at Support (for stirrups calculation), V = 87 KN Effective Length of Beam (for stirrups calculation), L = 5 m Reinforcing Bar Yield Strength, fy = 275 MPaYou must enter the minimum filament yield stress You can calculate the equivalent diameter as follows d = √(n₁d₁² n₂d₂² n₃d₃² n₄d₄² ) / (n₁ n₂ n₃ n₄ )

Yield Strength Strength Mechanics Of Materials Engineers Edge

Helical Spring Design Guide Xls

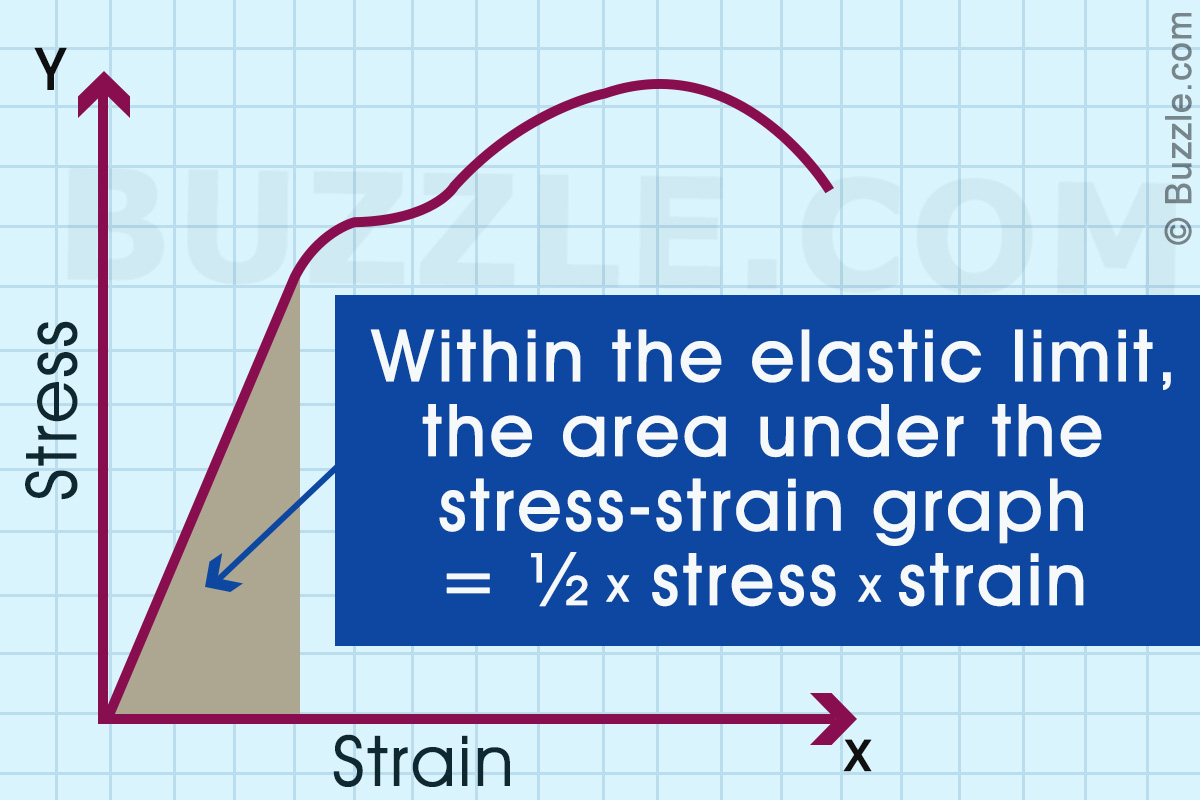

Strain energy per unit volume = 1/2 stress x strain Hence, Area = 1/2 stress x strain Where the graph is a curve, you will have to find out the equation of the curve and then integrate the curve within the limits of the graph The following formula is usedFirst, we rearrange the formula provided above to solve for F We already know that the allowable shear stress is 70,000 x 030 = 21,000 psi To get A (effective area of the weld) we need to multiply the theoretical throat size (1/4 x 0707 = 0177 inches) times the length ( inches) times 2 weldsBox and pin tensile rating To use the search algorithm, the user must enter the OD, ID, Pitch, and Yield Strength The program then takes over and performs the search based on the constraints input by the user After performing the algorithm, the program then displays the results in order of increasing maximum allowable tensile strength difference

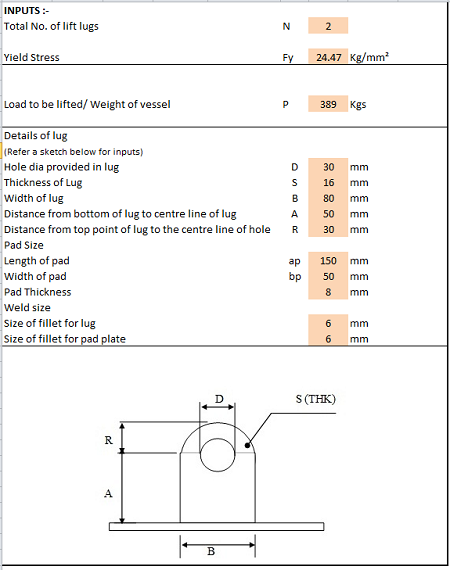

Lifting Lug Design Spreadsheet Download Agentcrack

How To Plot Stress Vs Strain Youtube

In this Microsoft Excel to create Stress/Strain Curves from a sample set of data and then determine the Young's Modulus from sample DataThis excercise is oUse the INDEX and LINEST function to calculate the intercept between 500 and 2500 microstrain =INDEX (LINEST (stress range, strain range),2) 4 Use these values to calculate an offset stress forY )= 530 MPa, Ultimate Strength= 625MPa Max Stress o The shaft is keyed for a 3/32" key, thus a close approximation for the actual yield strength is ¾ the materials yield strength (Keyed Yield Strength=398 MPa) o Loading is comprised of three components MomentBased on cantilevered distance from bearing and radial load exerted on shaft from the miter gear (21 Nm) Force Based on axial load exerted on shaft from miter gear ( N) Torque Exerted by the stall torque of the motor,

Search By Hardness Tensile Strength Tokushu Kinzoku Excel Co Ltd

Create A Custom Excel Spreadsheet For Your Various Needs By Adnantiro

The stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offsetDesign Shear at Support (for stirrups calculation), V = 87 KN Effective Length of Beam (for stirrups calculation), L = 5 m Reinforcing Bar Yield Strength, fy = 275 MPa Concrete Compressive Strength, fc' = 7 MPaSheet thickness (in) Die edge radius (in) Punch edge radius (in) Bend length (in) Ultimate tensile strength (psi) Factor of safety

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

Microsoft Excel Bond Yield Calculations Tvmcalcs Com

Barlow's Formula is an equation which shows the relationship of internal pressure, allowable stress, nominal thickness and diameter You can use Trident Steel's calculator tool to determine bursting pressure of line pipeTrident Steel offers ERW line pipe from international and domestic millsUse our calculator below or get a quote on line pipe todayUse this Online Yield Rate Calculator Calculator to get the desired metric in just a few clicks or download a free template in Excel Yield Rate Calculator is an easy and readytouse excel template to calculate the yield rate at each stage during the staffing process starting from receiving applications to recruiting the candidateWhere the graph is a straight line, you will have a triangular region, the area of which can be easily found out The area under the stressstrain graph is the strain energy per unit volume (joules per metre3) Strain energy per unit volume = 1/2 stress x strain Hence, Area = 1/2 stress x strain

Q Tbn And9gcsrdl8wwvejgxetlbntwved Q8j9af6bhbb1ktdahvmnxvkfkq8 Usqp Cau

The 0 2 Offset Method In Excel Youtube

For to X use a strain value large enough that the line will be certain to cross the stressstrain curveHow to calculate yield strength Contents hide show Description;Use the Yield Function to Calculate the Answer Type the formula "=Yield(B1,B2,,B4,B5,B6,)" into cell B8 and hit the "Enter" key The result should be percentwhich is the annual yield to maturity of this bond

Use The Tensile Data Given In A Separate Excel Fil Chegg Com

Stress Strain Curve Calculator Mechanicalc

If settlement or maturity dates are not valid, YIELD returns #VALUE!Pa = 4B (where B is ASME yield stress) & Step 7;3636 9 55,500 1265 4040 10 50,000 1408 4444 11 45,600 1542 4848 12 41,500 1697

Converting Engineering Stress Strain To True Stress Strain In Abaqus

Introduction To Reinforced Concrete Structural Design An Online Course For Engineers And Land Surveyors

Yield Strength Pin YS Pin ksi Yield Strength Box YS Box ksi Total Length of Engagement L E in Pin ID max ID Pin,max in Box OD min OD Box,min in Class Stub Acme Style 2G Tension Angle 145 degrees Compression Angle 145 degrees Friction Coefficient 13Guage Mil Micron in 2 /lb g/m 2;In addition to the common (qualitative) criteria, specific factors of the specific welded connection (type, workmanship and the way of connection load) must be considered when choosing the required safety The required safety for the yield strength "FSy" is then defined as the product of two safety coefficients FSy = FS1 * FS2

.jpg)

Yield Stress Calculation Methods

Solved Tensile Test Lab Report Guidelines 1 0 Objectives Chegg Com

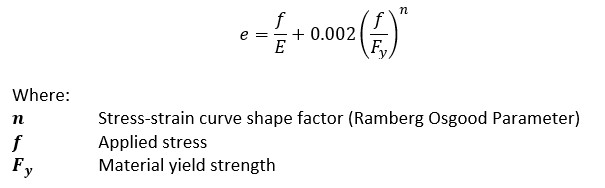

ASME VIII, Division 1, Part UG Factor 'A' Paragraph UG23, (b) Step 1 Factor 'B' Paragraph UG28, (c) Step 6;3636 9 55,500 1265 4040 10 50,000 1408 4444 11 45,600 1542 4848 12 41,500 1697The stressstrain curve is approximated using the RambergOsgood equation, which calculates the total strain ( elastic and plastic) as a function of stress where σ is the value of stress, E is the elastic modulus of the material, S ty is the tensile yield strength of the material, and n is the strain hardening exponent of the material which can be calculated based on the provided inputs

Finding 0 2 Offset Strain Dplot

Design Of Slab Two Way Excel Sheet

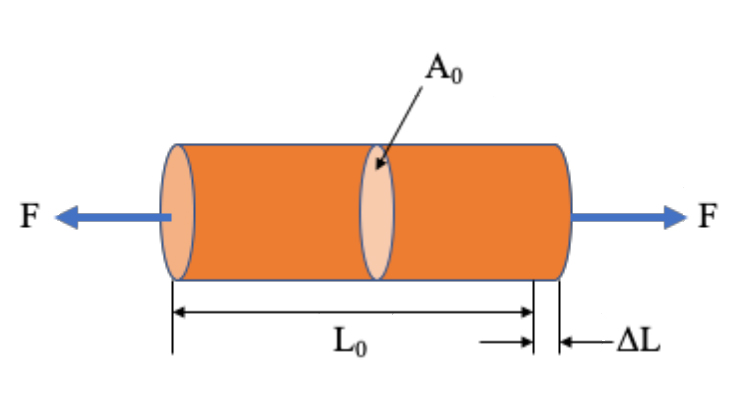

Simple Engineering Stress is similar to Pressure, in that in this instance it is calculated as force per unit area Stress can be calculated in a number of ways, however for calculating young's modulus, we will explore this methodStress Area formulae D = Basic Diameter p = Screw Thread Pitch L e = Length of Thread Engagement A t = The screw thread tensile stress area d p = Pitch circle diameter of thread A ss =The thread shear area The following formula for the Tensile Stress Area of the (male) screw This is based on ISO 8 Part 1 see calculation below d p = Pitch circle diameter of threadGuage Mil Micron in 2 /lb g/m 2;

How Can I Calculate The Young S Modulus Secant Modulus In The Stress Strain Curve Of Tensile Test

Calculating 0 2 Proof Stress Of Aluminium Physics Forums

You can use Excel's RATE function to calculate the Yield to Maturity (YTM) Check out the image below The syntax of RATE function RATE (nper, pmt, pv, fv, type, guess)Where Y cs = Yield point of continuous slot screen (lbs) S = Yield strength (mild steel = 35,000 psi) r = Radius of rods or diameter/2 (inches) n = Number of rods j = Joint efficiency of connection between screen and weld ring (generally assumed to be 070) sf = Safety factor (assumed for this example at 05) = pi orSheet thickness (in) Die edge radius (in) Punch edge radius (in) Bend length (in) Ultimate tensile strength (psi) Factor of safety

Material Properties

How To Draw A Line Parallel To The Linear Portion Of The Curve In Excel Stack Overflow

0 frequency is not 1,2, or 4;

Http Engin Swarthmore Edu Akrikor1 E6 labs E6lab2 Pdf

Stress Strain Curves In Excel Calculate Young S Modulus Youtube

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Calculate Proof Stress Youtube

Load Extension Diagram Leaving Certificate Engineering Notes

Http Www Iitk Ac In Mme Test Mme310 Pdf

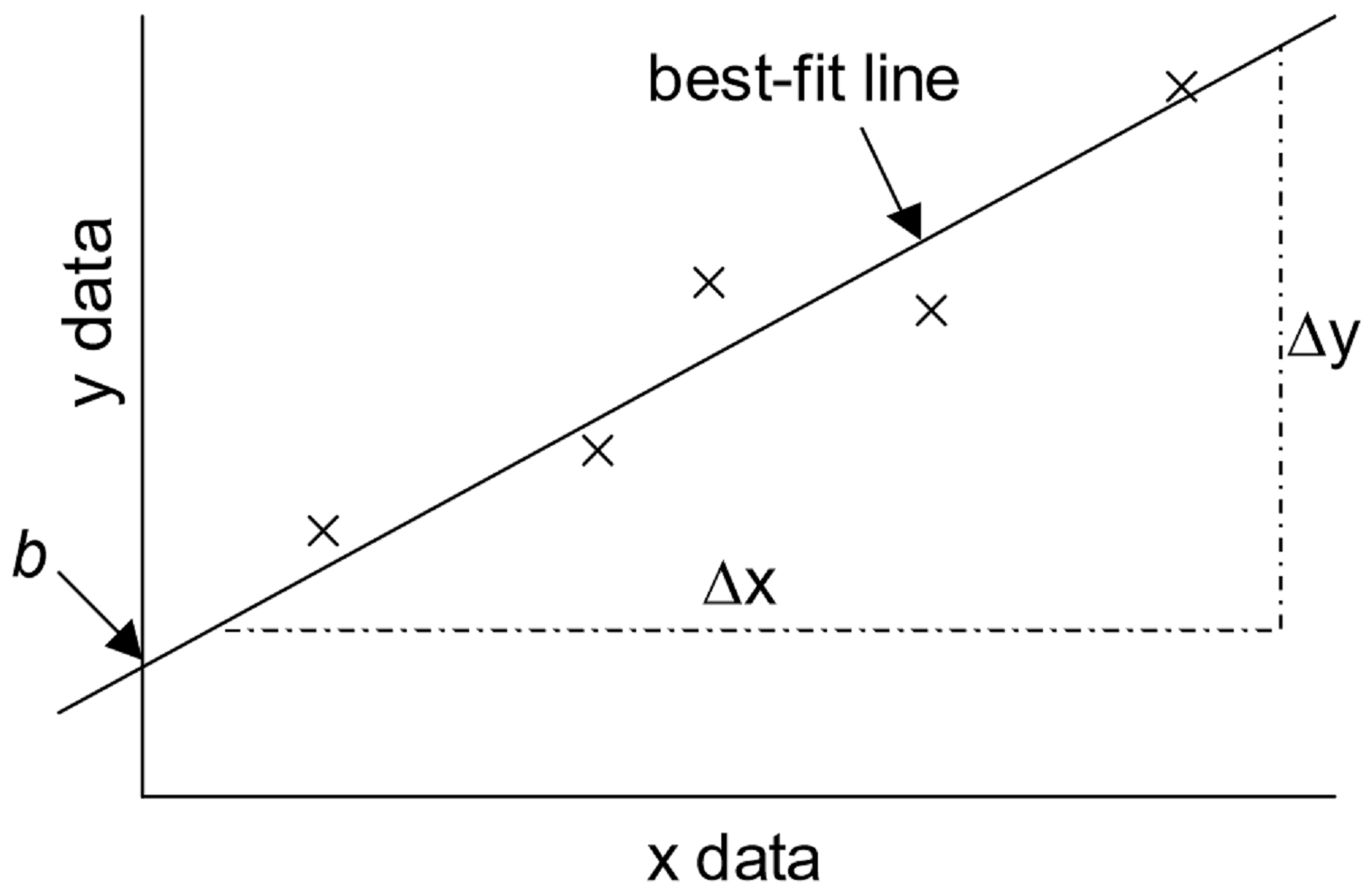

1 Using Excel For Graphical Analysis Of Data Experiment Chemistry Libretexts

Http Www Csun Edu Bavarian Courses Mse 527 Tension Test Mse 527l Pdf

How To Calculate Bond Yield In Excel 7 Steps With Pictures

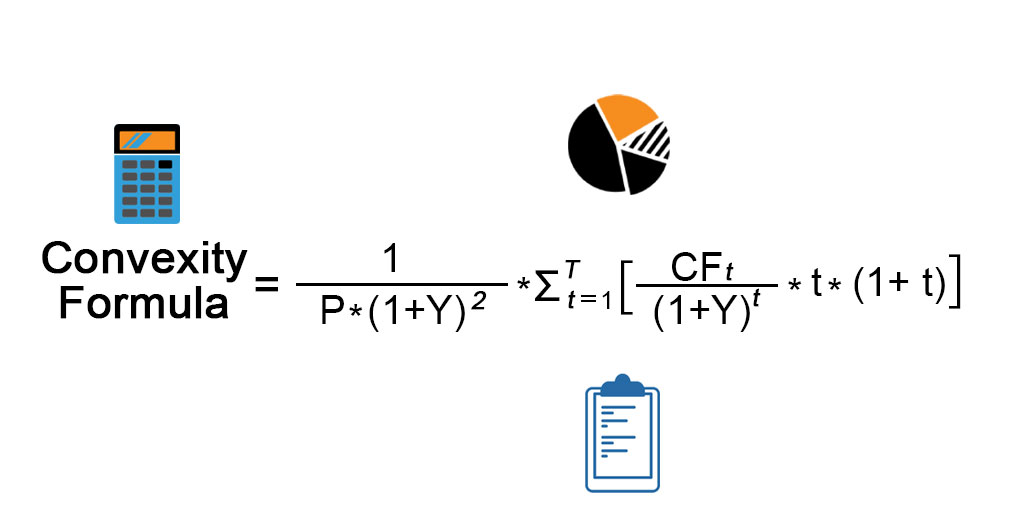

Convexity Formula Examples With Excel Template

Collapse Pressure Property For Oilfield Tubular Drilling Formulas And Drilling Calculations

Foundation And Column Calculation Excel File With Solved Example Civilengineeringbible Com

Ramberg Osgood Relationship Wikipedia

Pipe Flow Calculations Archives Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets

Yield Strength Strength Mechanics Of Materials Engineers Edge

Http Mtil Illinois Edu Data Dataanalysishelp Tensile Example Tensile Analysis Tensileexample Pdf

Spur Gear Calculator Tooth Profile Design Strength Calqlata

Tensile Testing Data Sheet Please Fill In Your Name Group Members Data And Instructor S Name Mark Gage Length Indents Using The Hammer Measure The Ppt Download

Microsoft Excel Bond Yield Calculations Tvmcalcs Com

How To Use The Excel Yield Function Exceljet

Stress Strain Curve For Steel And Resulting Points Of Interest Youtube

Plotting A Stress Strain Curve With Python And Matplotlib Python For Undergraduate Engineers

Determination Of Toughness Of A Sample From Its Stress Strain Tensile Curve What Unit Should We Assign To The Value Of Toughness

.jpg)

Yield Stress Calculation Methods

On Cyclic Yield Strength In Definition Of Limits For Characterisation Of Fatigue And Creep Behaviour

Yield Function Calc Bond Yield Excel Vba G Sheets Automate Excel

Excel Sheet Of A Tensile Test Is Uploaded Please Chegg Com

How To Draw A Line Parallel To The Linear Portion Of The Curve In Excel Stack Overflow

Baseplt9 Xls

T Beam Design Excel Sheet

A Brief Guide On How To Calculate Area Under The Stress Strain Graph Science Struck

Yield Strength Strength Mechanics Of Materials Engineers Edge

Estimation Of The Ramberg Osgood Material Shape Factor In The Plastic Range

Modulus Of Elasticity Instron

Flange Leakage Evaluation Based On Nc 3658 3 Method Method Using Caesar Ii What Is Piping All About Piping Engineering

Http Mtil Illinois Edu Data Dataanalysishelp Tensile Example Tensile Analysis Tensileexample Pdf

What Is 0 2 Of Offset Method In Yield Strength Quora

How To Draw 0 2 Offset Line On A Stress Strain Graph Youtube

Civl 1101

Solved The Tensile Test Data Provided In The Excel File S Chegg Com

Project In Excel 2

How Is Clamp Force For A Bolt And Nut Assembly Calculated Security Locknut

Lifting Lug Design Spreadsheet Download Agentcrack

Finding 0 2 Offset Strain Dplot

Stress Strain Plotter File Exchange Matlab Central

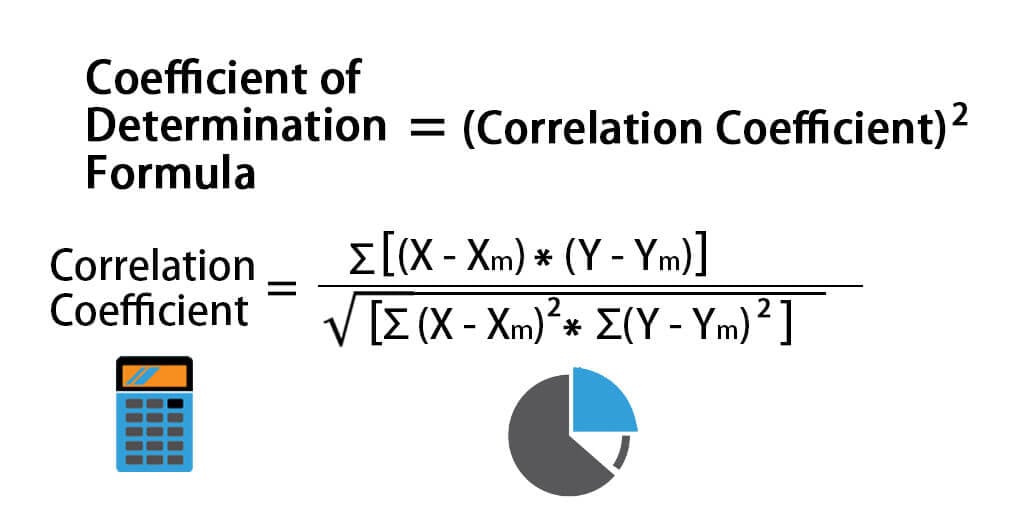

Coefficient Of Determination Formula Calculation With Excel Template

Http Maecourses Ucsd Edu Jmckittr Mae Wi11 Assignment 5 solutions Pdf

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

Stress And Strain Mechanical Properties Of Materials

Strength At Break Tensile

Astm E8 Measuring The Tensile Strength Of Metals

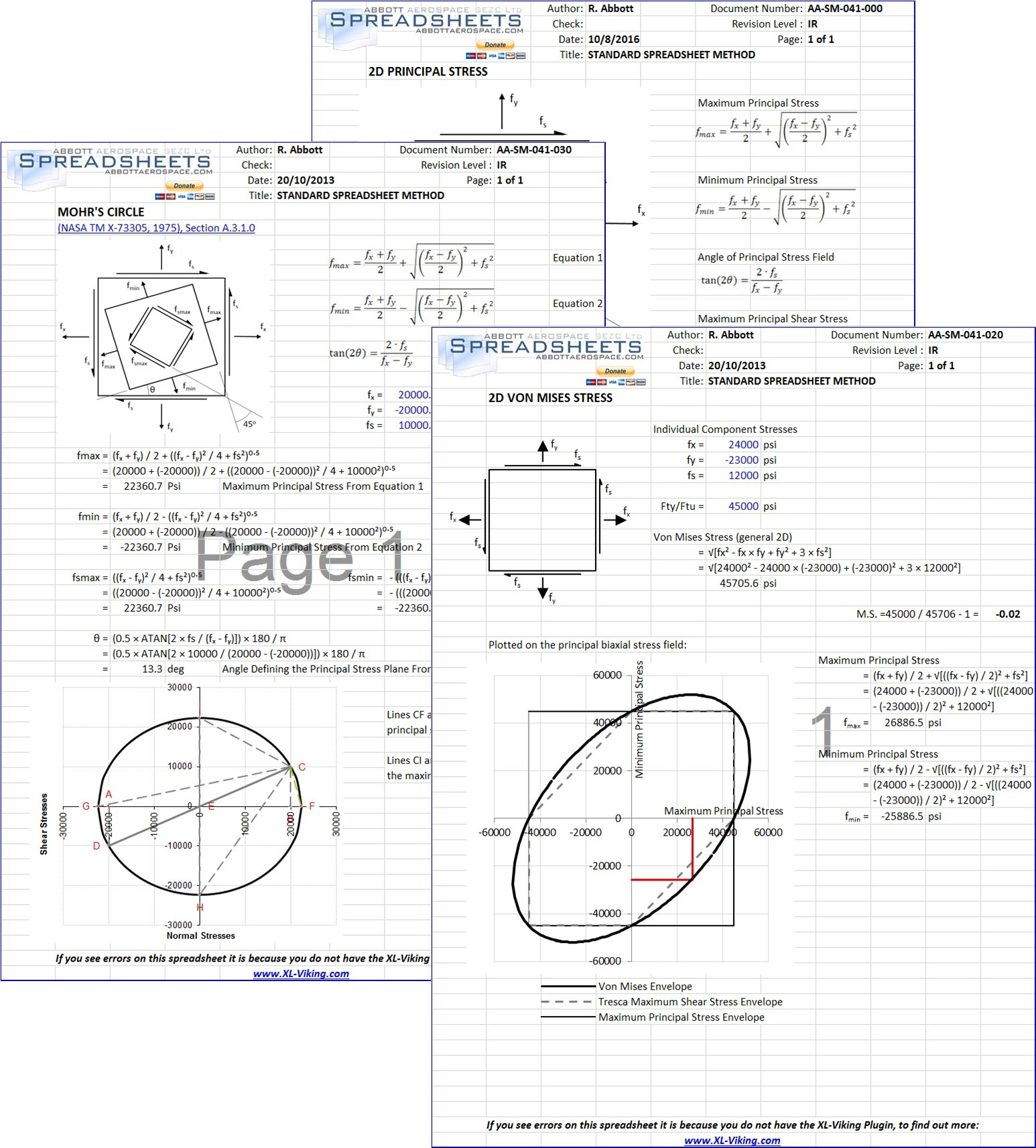

New Stress Analysis Spreadsheets Von Mises And Principal Stresses Abbott Aerospace Canada Ltd

Http Maecourses Ucsd Edu Jmckittr Mae Wi11 Assignment 5 solutions Pdf

On Cyclic Yield Strength In Definition Of Limits For Characterisation Of Fatigue And Creep Behaviour

Exploring The Stress Strain Curve For Mild Steel The Chicago Curve

Http Mtil Illinois Edu Data Dataanalysishelp Tensile Example Tensile Analysis Tensileexample Pdf

How To Draw A Line Parallel To The Linear Portion Of The Curve In Excel Stack Overflow

Civl 1101

Material Selection Chart An Overview Sciencedirect Topics

Stress Strain Analysis On Excel Youtube

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

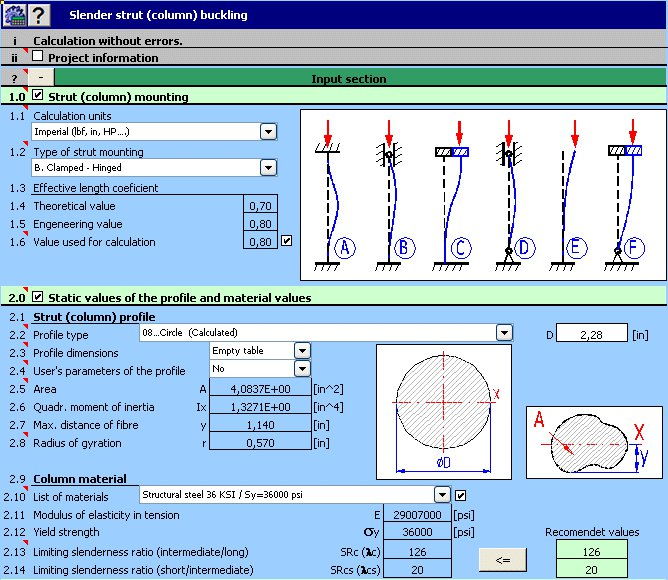

Mitcalc Buckling Calculation Slender Strut Column Buckling Spreadsheet

Stress And Strain Mechanical Properties Of Materials

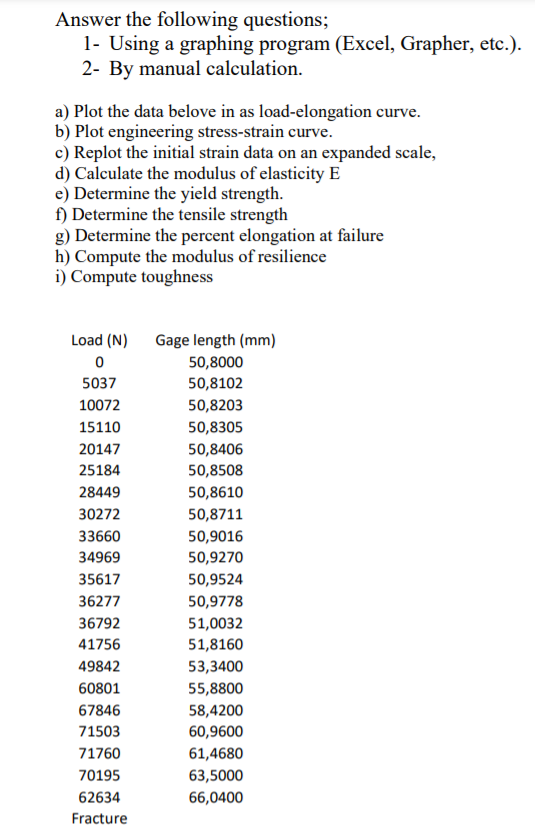

Solved Answer The Following Questions 1 Using A Graphin Chegg Com

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Bolted Joint Analysis Calculator Mechanicalc

Q Tbn And9gcs4 Kmbc0eevoesao31ukydn0fpdox Dykxkecqwqlk4eh7dc9j Usqp Cau

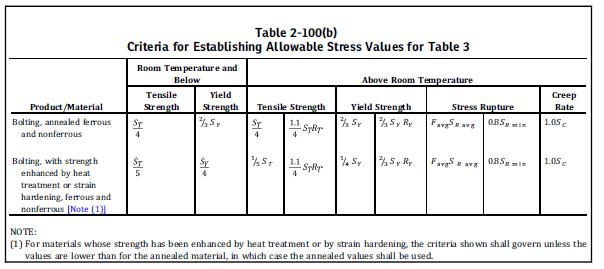

Asme Section Ii Part D Allowable Stresses Elysium Industries Inc

コメント

コメントを投稿